How Digital Workflow Management Revolutionizes Custom Manufacturing Operations

Custom manufacturing businesses face unique challenges that mass production facilities never encounter. From managing variable order specifications to coordinating multiple one-off projects, custom manufacturers like furniture makers, window fabricators, and architectural metalworkers need specialized solutions to thrive. Digital workflow management systems are transforming how these businesses operate, delivering unprecedented efficiency and customer satisfaction.

The Unique Challenges of Custom Manufacturing

Managing Variable Order Specifications

Unlike mass production, custom manufacturing means every order is unique. A furniture maker might receive an order for a custom dining table with specific dimensions, wood species, and finish requirements, while the next order could be a completely different style of chair. This variability creates significant complexity throughout project planning and resource allocation, material procurement and inventory management, production scheduling and capacity planning, and even quality control processes that must adapt to each unique specification.

Coordinating Multiple Custom Projects Simultaneously

Custom manufacturers often juggle dozens of unique projects at different stages of completion. A window manufacturer might have 15 different custom window orders in various phases: some in design, others in material preparation, several in production, and a few in finishing. Without proper workflow management, this complexity creates a cascade of problems—project delays and missed deadlines become commonplace, resource conflicts and bottlenecks emerge unexpectedly, communication breakdowns occur between teams, and ultimately, customers grow dissatisfied, sometimes taking their business elsewhere.

Tracking Unique Materials and Components Per Order

Each custom order requires specific materials, often with long lead times or limited availability. An architectural metalwork company might need custom steel profiles for one project, while another requires specialized hardware or finishes. Traditional inventory management systems struggle with this level of specificity. The result? Material shortages that delay projects, excess inventory of unused materials gathering dust, difficulty tracking material costs accurately for each project, and significant waste that erodes profit margins.

Why Traditional Methods Fail in Custom Manufacturing

Spreadsheet Chaos with One-Off Orders

Many custom manufacturers rely on spreadsheets to manage their projects, but this approach quickly becomes unmanageable. As the number of unique orders grows, spreadsheets become cluttered with inconsistent data entry and formatting. Multiple versions of the same information float around the organization, project dependencies become impossible to track, and real-time visibility into project status? Forget about it. By the time you update the spreadsheet, the information is already outdated.

Communication Breakdowns Between Sales, Design, and Production

Custom manufacturing requires seamless communication between sales teams (who understand customer requirements), design teams (who create technical specifications), and production teams (who execute the work). Yet traditional communication methods—emails, phone calls, printed work orders—create a perfect storm for misunderstandings. Customer specifications get lost in translation, design approval processes drag on for days, production teams work from unclear or outdated instructions, and customers grow increasingly frustrated waiting for project updates that never come.

Difficulty Tracking Project Progress Across Different Stages

Custom manufacturing projects typically move through multiple stages: quote, design, material procurement, production, finishing, and delivery. Without proper tracking, each stage becomes a black box. Project status and timelines remain unclear, bottlenecks hide in plain sight until they become crises, providing accurate customer updates feels like guesswork, and capacity planning becomes more art than science—usually with disappointing results.

The Digital Workflow Advantage for Custom Manufacturers

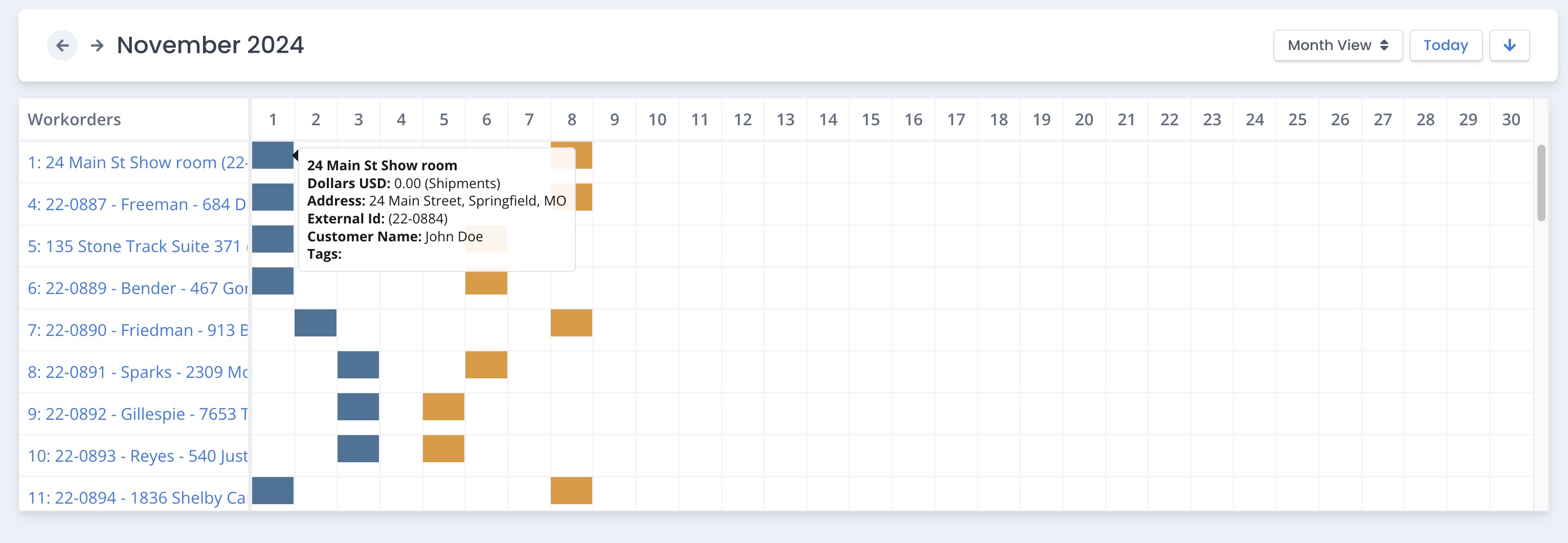

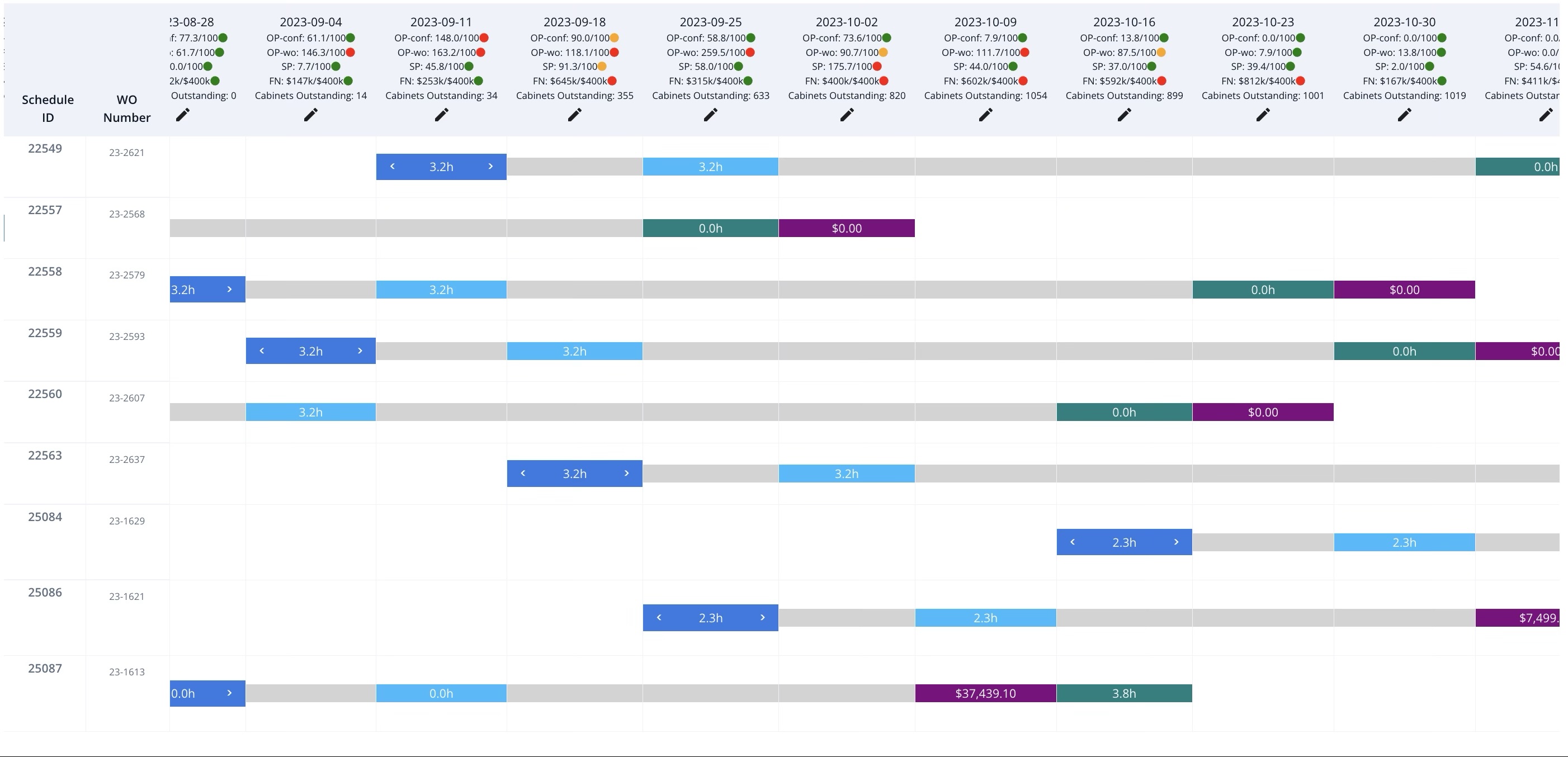

Project-Specific Scheduling and Resource Allocation

Digital workflow management systems excel at handling the complexity of custom manufacturing by providing project-specific scheduling capabilities. Imagine creating detailed project timelines based on each order's unique requirements, then watching as the system intelligently allocates resources based on project complexity and priority. These systems track dependencies between different project phases automatically, and when delays inevitably occur, schedules adjust dynamically to minimize impact across your entire production floor.

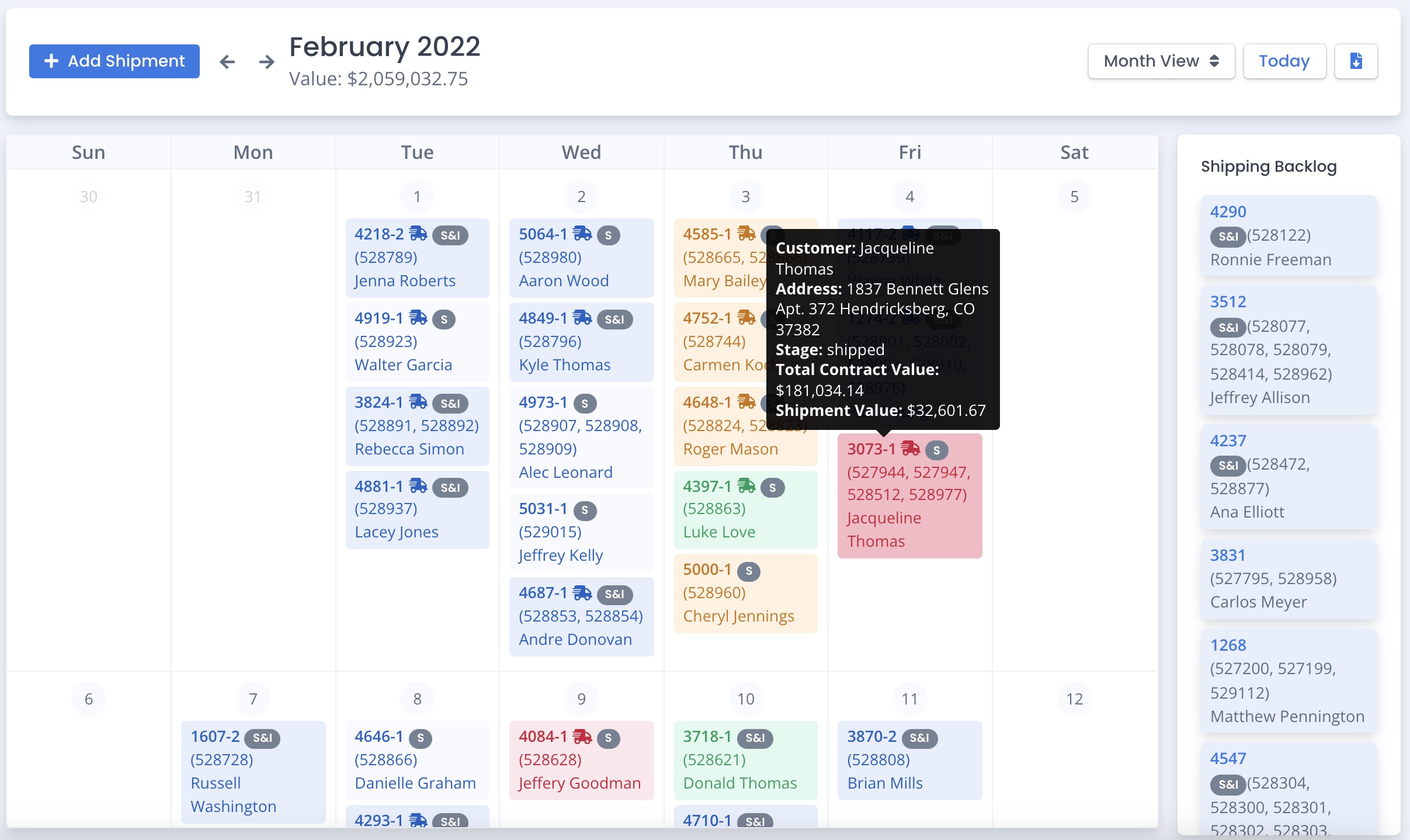

Real-Time Order Tracking from Quote to Delivery

Modern workflow systems provide complete visibility into each custom order's journey. From the moment a customer inquiry arrives through final delivery, every stakeholder can track project progress in real-time. This transparency allows teams to identify potential delays before they impact customers, provide accurate delivery estimates with confidence, and maintain detailed project histories that become invaluable for quoting similar work in the future.

Integrated Design-to-Production Workflows

Digital systems bridge the gap between design and production by creating seamless workflows. Design specifications automatically transfer to production teams—no more lost paperwork or outdated drawings on the shop floor. All project stakeholders have instant access to current information, design changes and approvals flow smoothly through established channels, and version control for project documentation happens automatically, ensuring everyone always works from the latest specifications.

Automated Material Planning for Unique Orders

Advanced workflow systems can automatically generate material requirements based on project specifications. The system calculates exact material needs for each project, identifies potential material conflicts and suggests alternatives, tracks material costs per project with precision, and helps optimize material usage to reduce waste. For custom manufacturers operating on tight margins, this level of material intelligence can be the difference between profit and loss on a project.

Key Benefits for Custom Manufacturers

- Reduced Project Delays and Missed Deadlines: Digital workflow management provides real-time visibility into project status, enabling proactive identification and resolution of potential delays before they impact customers.

- Better Customer Communication and Project Visibility: Customers can track their custom orders in real-time, receive automatic updates, and have clear visibility into project progress and delivery timelines.

- Optimized Material Usage and Waste Reduction: Automated material planning and tracking help custom manufacturers optimize material usage, reduce waste, and improve cost control for each unique project.

- Improved Quality Control for One-Off Products: Digital systems ensure that quality control checkpoints are properly tracked and documented for each custom order, maintaining consistent quality standards.

- Enhanced Team Coordination and Communication: All project stakeholders have access to current project information, reducing miscommunication and ensuring everyone is aligned on project requirements and timelines.

- Scalable Operations Management: As custom manufacturing businesses grow, digital workflow systems can scale to handle increasing project complexity and volume without proportional increases in administrative overhead.

Real-World Success Stories

Custom Furniture Manufacturer Transformation

A mid-sized custom furniture manufacturer was struggling with project delays and customer communication issues. Their shop floor was constantly in motion, but not always in the right direction. After implementing a digital workflow management system, the transformation was dramatic: project delivery times dropped by 40%, customer satisfaction soared from 78% to 95%, material utilization improved by 30%, and perhaps most importantly, their team spent 50% less time on administrative tasks, freeing them to focus on what they do best—crafting beautiful custom furniture.

Window and Door Manufacturer Case Study

A custom window and door manufacturer with 25 employees was managing 50+ projects simultaneously using spreadsheets and whiteboards. The chaos was palpable—project managers spent hours reconciling conflicting information, production delays were frequent, and customer calls asking "where's my order?" had become routine. The implementation of digital workflow management changed everything. Project tracking errors vanished almost overnight. The team gained real-time visibility into production capacity, allowing them to commit to realistic delivery dates. Material ordering became automated based on project specifications, and the coordination between design and production teams improved dramatically. Today, they handle even more projects with less stress.

Architectural Metalwork Company Success

An architectural metalwork company specializing in custom railings and structural elements implemented digital workflow management to handle complex, high-value projects. Before the switch, they were leaving money on the table—literally. Without accurate cost tracking, they couldn't pinpoint which projects were profitable and which weren't. The digital system changed that, giving them precise project profitability data. Client relationships improved through transparent project communication (clients loved being able to see progress updates), rework and quality issues decreased significantly, and the team gained the confidence to take on larger, more complex projects they previously would have declined.

Implementation for Custom Manufacturers

Adapting Digital Tools for Variable Production

Custom manufacturers need workflow systems that can handle the variability inherent in their business. The right system offers flexible project templates that can be customized for different order types—because no two custom jobs are alike. Look for configurable workflow stages that match your specific production process rather than forcing you to adapt to a rigid system. Integration capabilities with existing design and production software are essential; your new system should complement your current tools, not replace them all. And perhaps most importantly for growing businesses, seek out scalable pricing models that grow with your business rather than requiring massive upfront investments.

Managing Customer Specifications Digitally

Digital workflow systems should provide comprehensive tools for capturing detailed customer requirements and specifications from the very first conversation. All project documentation and drawings need a centralized home where everyone can find the latest version. Customer approvals and change requests—always a source of confusion in custom work—should be tracked automatically, creating a clear paper trail. And maintaining detailed project history isn't just good practice; it becomes a competitive advantage when quoting similar work or winning repeat business from satisfied customers.

Scaling from Small Custom Shops to Larger Operations

The beauty of modern digital workflow management systems is their ability to grow with your business. A good system features user-friendly interfaces that don't require extensive training—your team should be productive within days, not months. Mobile access for field workers and managers keeps everyone connected, whether they're on the shop floor, at a client site, or working remotely. Seamless integration with existing business systems protects your technology investments, and flexible deployment options—cloud-based or on-premises—let you choose what works best for your operation and security requirements.

Getting Started with Digital Workflow Management

For custom manufacturers ready to embrace digital transformation, the journey begins with understanding your current processes and identifying areas for improvement. Start by mapping your current project workflow from quote to delivery—really document how work flows through your shop today, not how you wish it did. Then identify the pain points and bottlenecks in your process; ask your team where things consistently go wrong or slow down.

Next, evaluate digital solutions that match your specific needs rather than trying to fit your business into a one-size-fits-all system. When you find a promising solution, start with a pilot project to test the system with real work before committing fully. This approach lets you work out the kinks and build confidence. Finally, gradually roll out the system across all projects, learning and adjusting as you go.

The custom manufacturing industry is evolving rapidly, and businesses that embrace digital workflow management will have a significant competitive advantage. By providing better project visibility, improved customer communication, and enhanced operational efficiency, digital systems enable custom manufacturers to deliver exceptional results while growing their business profitably. The question isn't whether to digitize—it's how quickly you can make the transition before your competitors do.

PlanBoard offers specialized workflow management solutions designed specifically for custom manufacturing businesses. Our platform provides the flexibility and power needed to manage complex, variable production while maintaining the simplicity required for small to mid-sized operations. Sign up for a free account today and discover how digital workflow management can transform your custom manufacturing operations.